From discussing process enhancements to repairing broken equipment and everything in between, it’s just another day for this connected tech. Each week he spends as much or as little time needed to keep our food and beverage partner running smoothly and efficiently.

8:00 am – 9:00 am

Orville starts each Monday by meeting with management to discuss any open projects. During this week’s discussion, management asks his opinion on a possible weigh module upgrade. Together, they examine the existing setup and identify the pros and cons of upgrading to new Mettler Toledo weigh modules.

9:00am -9:45am

After his meeting, Orville heads to his first project for the day. One of the steam kettles is weighing incorrectly and needs to be returned to service ASAP. After a quick troubleshoot, Orville discovers a broken mounting bolt. A few wrench turns later and the kettle is back in service. His swift diagnosis and fix allowed the food line to return to regular production with minimal interruptions.

9:45am -10:00am

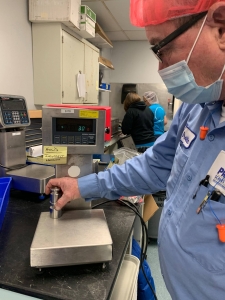

Orville then moves to the next room over to perform a few quick adjustments to a newly installed IND 570 terminal. These small modifications will ensure quick accurate weighing with minimal downtime.

10:00am -10:30am

For his last scheduled stop, Orville makes a quick stop to the quality lab. The lab has reported erratic readings on a bench scale. After another round of troubleshooting, Orville determines a faulty loadcell is the culprit. Since it’s a non-critical piece of equipment, he can repair the scale during the week and bring it back during next week’s visit.

10:30am -11:00am

Occasionally stopping to move scales away from a wall and remove potential obstructions, Orville finishes his day by walking the facility. This trip isn’t for extra steps, it’s to identify any scale or metrology issues that may not have may have gone unnoticed or could lead to bigger issues down the road.

10:30am -11:00am (Cont’d)

Since this is a washdown facility, hoses and high-pressure water can do a number on cable mounts. During his facility check, Orville pays extra attention to homerun cables and drip loops that may have been dismounted during the previous week’s cleanings.

Want a connected tech for your facility?

Visit our connected tech page to learn the three easy steps to get your very own Connected Tech or fill out the form below for more information.