Ensuring the Perfect Pint Every Time

In brewing, precision is the key ingredient that often goes unnoticed. Behind every sip of is a meticulous process driven by accurate measurements. From the amount of hops and malt used to the liquid levels in fermenters, precision ensures that each pint is consistent, flavorful, and up to the brewer’s standards. Metrology guarantees that these crucial elements are monitored and maintained throughout the brewing process, ensuring that every batch meets the highest quality standards.

Precision in Every Batch

In brewing, small variations in weight or volume can lead to big differences in taste. Metrology ensures that the right amount of grain, hops, and water goes into every batch, and it helps monitor processes like fermentation and bottling. By using precise measuring tools, brewers can maintain consistency, ensuring that each sip tastes exactly as intended.

Key Equipment in Breweries

Metrology in brewing requires accurate measurement tools like weighing modules, tank scales, and load cells play a vital role in ensuring precision at every stage of the brewing process. From controlling ingredient proportions to verifying the fill levels of bottles and cans, this equipment guarantees consistency and quality in every batch.

Weighing Modules and Tank Scales:

Fermentation and storage tanks need to be carefully monitored. Accurate tank scales help brewers ensure that their batches stay within the right parameters, maintaining proper volumes, preventing errors, and ensuring legal compliance.

Load Cells:

These sensors are critical for measuring the weight of raw ingredients. Whether it’s barley, hops, yeast, or water, precise weighing ensures that the right ratios are maintained for every batch, which is key to producing consistent results.

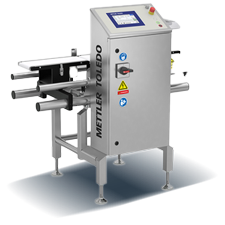

Checkweighers:

At the packaging stage, checkweighers ensure that every bottle and can is filled to the correct weight. This not only ensures compliance with regulations but also guarantees that every customer gets exactly what they expect in terms of quality and quantity.

The Role of Calibration

Brewing equipment is highly sensitive, and even the slightest deviation in calibration can lead to subpar results. Calibration ensures that equipment like scales, load cells, and checkweighers are providing accurate readings. Regular calibration helps breweries maintain consistent product quality while reducing waste and optimizing processes.

Why Metrology Matters

In the competitive world of craft brewing, metrology provides the precision needed to consistently produce high-quality beer. Accurate measurements are essential not only for consistency but also for cost efficiency. By reducing waste and ensuring that every drop of beer is accounted for, metrology supports a brewery’s bottom line while delivering great-tasting beer to customers.

Bottom Line

At Premier Scales & Systems, we are proud to serve the brewery industry by providing essential precision measurement solutions that help brewers maintain consistency and quality. We understand the unique challenges that breweries face, from ensuring the accurate dosing of raw materials to precise monitoring of tank levels during fermentation. Our ISO/IEC 17025 accredited calibration services ensure that equipment like tank scales, load cells, and checkweighers are delivering accurate readings, reducing waste and improving operational efficiency. With decades of experience and a commitment to excellence, we help breweries stay on top of their game, ensuring every batch is as perfect as the last.