A Field Guide to Identifying Various Gauges

Dimensional gauges play a crucial role in the field of metrology, ensuring precision and accuracy in the measurement of physical dimensions of objects. These instruments are indispensable in manufacturing, engineering, and quality control processes. Understanding the different types of gauges and their applications is essential to selecting the right gauge for your needs. The following is a detailed field guide to identifying various gauges in metrology.

Micrometers

Micrometers offer higher precision compared to calipers and are ideal for measuring small dimensions with great accuracy. There are different types of micrometers, including outside, inside, and depth micrometers, each designed for specific applications. Despite their precision, micrometers require proper handling to avoid measurement errors due to varying applied force.

Calipers

Calipers are versatile tools used for measuring internal and external dimensions as well as depths. They come in various forms such as vernier, dial, and digital calipers. While calipers are easy to use and provide a wide range of measurements, their accuracy depends significantly on the operator’s skill and consistency.

Snap Gauges

Snap gauges are used for quick and accurate measurement of external dimensions such as diameters of shafts and lengths of objects. They are available in fixed and adjustable types. Fixed snap gauges provide high precision for specific measurements, while adjustable snap gauges offer flexibility for a range of sizes.

Thread Gauges

Thread gauges are specialized tools for checking the pitch and diameter of threads. They include plug gauges for internal threads and ring gauges for external threads. These gauges ensure that threads meet the specified tolerances and are crucial for applications involving threaded components.

Radius and Fillet Gauges

Radius and fillet gauges measure the curvature of surfaces, ensuring the radii of convex and concave surfaces meet design specifications. These gauges are essential in quality control processes where the precise curvature is critical.

Feeler Gauges

Feeler gauges consist of a set of thin metal strips of varying thicknesses and are used to measure gap widths or clearance between parts. They are particularly useful in automotive applications for setting valve clearances and other similar tasks.

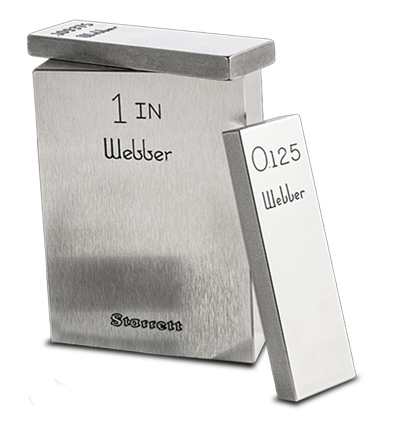

Blocks Gauges

Also known as gage blocks, these precision-ground blocks are used to calibrate and measure lengths with extreme accuracy. They rely on the process of wringing, where the blocks adhere to each other to form a precise length.

Bottom Line

Selecting the right dimensional gauge depends on the specific measurement requirements, the precision needed, and the nature of the parts being measured. Understanding the capabilities and limitations of each type of gauge ensures accurate and reliable measurements, which are critical for maintaining quality and consistency in manufacturing and engineering processes. Like all precision instruments, gauge blocks require special care and maintenance in order to maintain their accuracy. At Premier Scales & Systems, our ISO/IEC 17025 accredited calibration lab is ready to tackle virtually any type of block calibration.