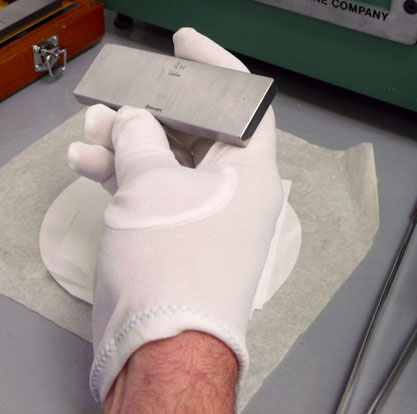

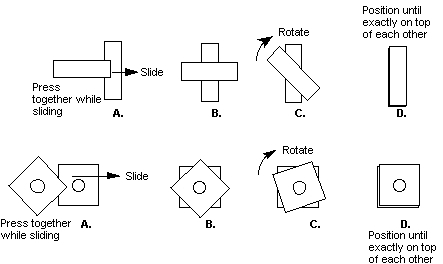

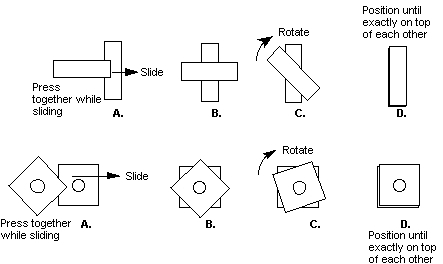

Wringing is the process of combining multiple gauge blocks to achieve a desired length. Once wrung, the blocks should stick together as if by a magnetic force. The first step of wringing gauge blocks is surface preparation. This is achieved by wiping the wringing surface a lightly oiled pad followed by a dry pad. There should be no excess oil visible. Once prepared, slide the blocks together using the image. The sliding motion should be smooth without bumps or abrasion. If either is present, immediate stop and inspect the surface for nicks or debris. When nicks are present, the gauge block should be set aside for stoning and calibration. To deal with debris, repeat the cleaning and oiling directions specified earlier. Although many processes do not require wrung gauge blocks, it can be a good way to check surface conditions. Gauge blocks that cannot be wrung may not be completely smooth.