The Crucial Role of Precision Scales

in the Pharmaceutical Industry

In the highly regulated pharmaceutical industry, precision scales are indispensable tools that ensure the accuracy and reliability of measurements. These scales play a pivotal role in various stages of drug development and manufacturing, from formulation to quality control, thereby ensuring the safety and efficacy of pharmaceutical products.

The Importance of Precision Scales

1. Accurate Drug Formulation: Precision scales are essential in the formulation of pharmaceutical drugs. Accurate measurement of active pharmaceutical ingredients (APIs) and excipients is critical to ensure the correct dosage and efficacy of the medication. Even a minor deviation in measurement can lead to significant differences in drug performance, potentially compromising patient safety.

2. Quality Control: In the pharmaceutical industry, maintaining high standards of quality control is non-negotiable. Precision scales are used to verify that the weight of tablets, capsules, and other dosage forms meet stringent regulatory requirements. This ensures consistency across production batches and compliance with Good Manufacturing Practices (GMP).

3. Regulatory Compliance: The pharmaceutical industry is subject to rigorous regulatory oversight from bodies such as the FDA, EMA, and WHO. Precision scales help manufacturers comply with these regulations by providing reliable and traceable measurement data. This data is crucial for regulatory submissions and audits, demonstrating that products meet all necessary quality standards.

4. Cost Efficiency: By ensuring accurate measurements, precision scales help minimize waste of costly pharmaceutical ingredients. This not only reduces production costs but also supports environmental sustainability by minimizing the disposal of unused or off-specification materials.

Types of Precision Scales Used in Pharmaceuticals

Analytical Balances:

Analytical balances are highly sensitive and can measure small mass variations with extreme accuracy, often up to 0.0001 grams. These are used for tasks requiring meticulous precision, such as weighing minute quantities of active ingredients.

Microbalances and Ultra Microbalances:

For even higher precision needs, microbalances and ultra microbalances offer unparalleled accuracy, measuring down to micrograms. These are critical in research and development laboratories where the utmost precision is required.

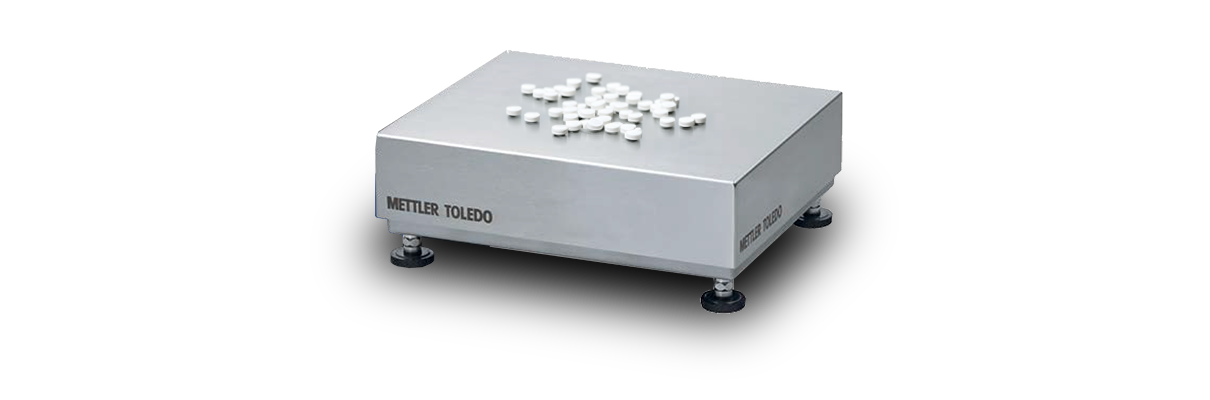

Bench Scales:

Bench scales, such as PBK and PFK (floor) scales, are versatile and used for weighing larger quantities of materials. While not as precise as analytical balances, they are still essential for bulk processing and quality control applications within the pharmaceutical industry.

Ensuring Precision and Accuracy

1. Calibration: Regular calibration, or calibration schedules, of precision scales is vital to maintain their accuracy. Calibration involves comparing the scale’s measurements to a standard of known mass and adjusting as necessary. This process should be conducted by certified professionals, such as the ones at Premier Scales & Systems, to ensure compliance with industry standards.

2. Environmental Control: Environmental factors such as temperature, humidity, and air currents can affect the performance of precision scales. Implementing environmental controls, such as using anti-vibration tables and controlling the room’s climate, can help mitigate these effects and ensure accurate measurements. Premier Scales & Systems has a state-of-the-art metrology lab capable of handling such controlled environments.

3. Proper Training: Ensuring that personnel are adequately trained in using precision scales is essential. Proper training minimizes user errors and ensures that the scales are used correctly, maintained properly, and calibrated regularly.

4. Procedures: Ensuring that operators know the proper procedures for using precision scales and balances is crucial. Again, proper training is needed in order to use precision scales correctly and avoid user errors which can lead to increased costs.

Bottom Line

Precision scales are a cornerstone of the pharmaceutical industry, ensuring that every step from drug formulation to quality control is performed with the highest accuracy. By understanding the critical role these scales play, pharmaceutical companies can ensure product safety, efficacy, and compliance with regulatory standards, ultimately safeguarding public health.